Air-conditioned chambers TNV

- The installation is designed for the first phase of the production of not heat-treated meat products; for the fermentation of products after they are put into packages and cold smoked (mostly first five to seven days of the process).

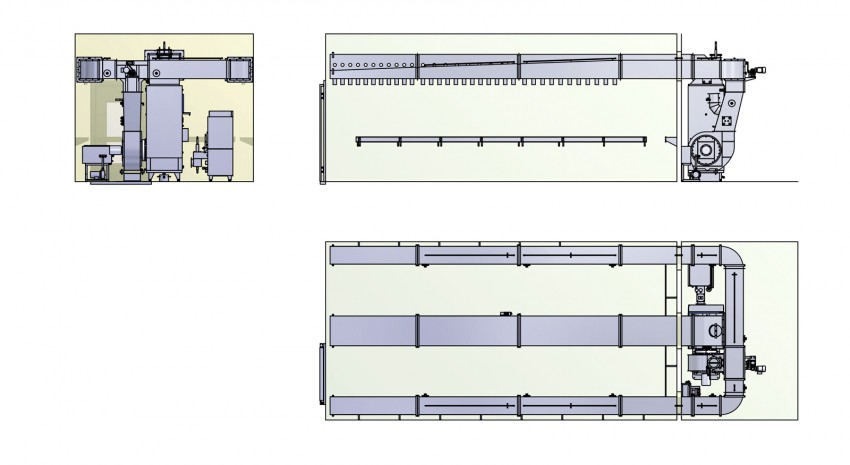

- Mostly installed in a place where construction works had already been done by the customer and which had already been divided into a part with an air-conditioned chamber and a machine room where the technology is placed.

- The temperature, humidity and air circulation is regulated by a control system iRauch, where a frequency converter controls revolutions of ventilator. This all helps to ensure optimal conditions of a product with reference to the technological requirements of product's ripening and optimization of slowing down the evaporation of water in it.

- It uses economical low-temperature drying with the condensation of water stream on the cooler's plate.

- The installation consists of air distributions, air-conditioner, controlled automatic smoke-producer and wash system.

- During the whole smoking procedure a controlled Smoke-generator Natural is regulated in the temperature extent of pyrolysis frass that is optimal for the production of smoke with qualities required for product smoking.

- All parts of the installation are specially designed for each customer according to the conditions, product assortment and differences in technology production.

- The installation includes an automatic wash-system which ensures the wash-up of all inaccessible parts of the smokehouse.

- The whole installation is made of stainless steel.