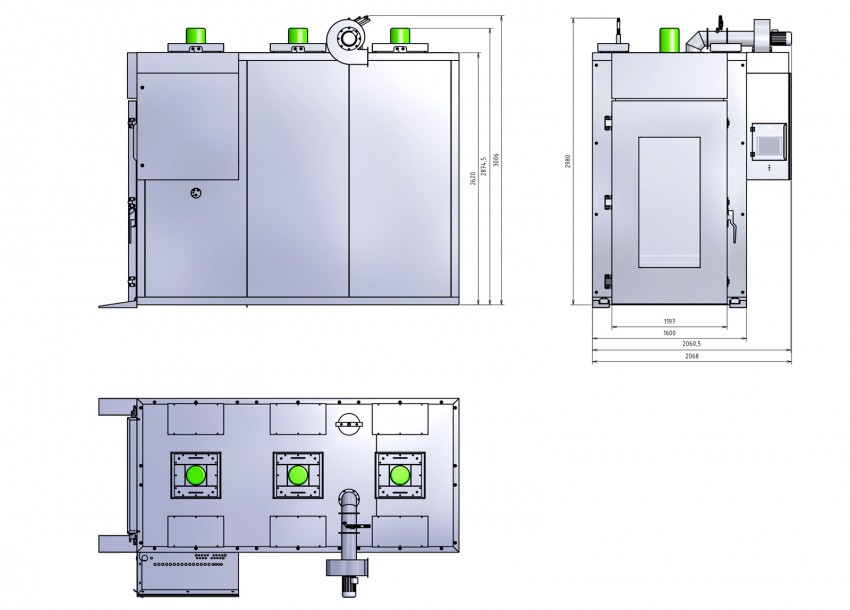

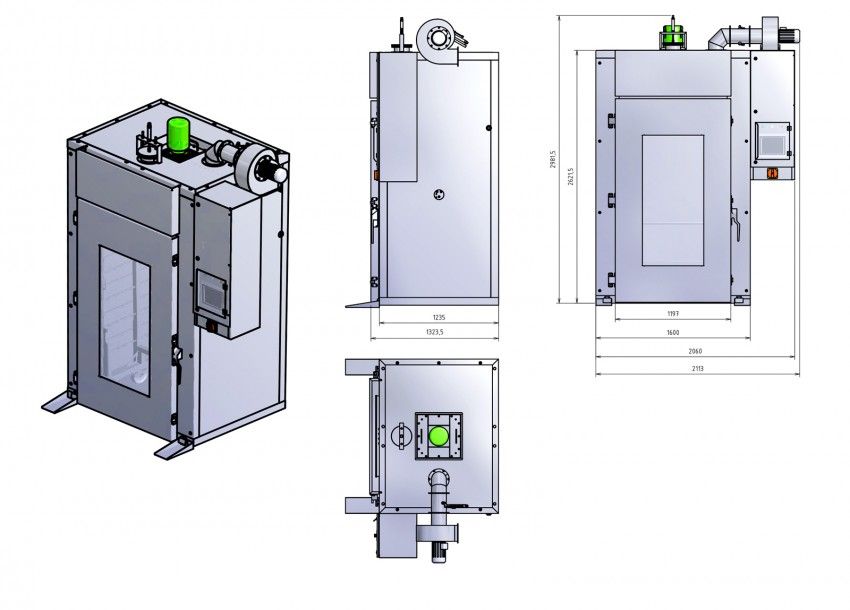

Cooking chambers

- The installation is designed for cooking of meat products, meat, fish, vegetables in steam, where the smoking is not required, or products in hermetic packaging where the smoking is needless.

- The technological process is controlled by a system that ensures automatic running of the cooking chamber. Its software enables arbitrary phase sequencing of the technological process as well as creation of user programs with different parameters (temperature, humidity, time, air circulation, cooking to the required core temperature, heat treatment according to delta-t) in each phase of the process. It also ensures the monitoring and recording of smokehouse parameters with reference to HACCP and Food Quality Control Inspection.

- Its case is made of several parts which are put together at the customers'. No assembling gap is needed as each of its parts can go through ordinary door. The housing of the installation's parts is made of stainless steel and afterwards filled on a special production line with bi-component polyurethane foam which is stabilized by pressure and temperature. Thanks to this, a perfect thermal isolation of chamber walls, or more precisely ecological and economic running of the chamber, is guaranteed.

- According to the customer's requirements the installation can be made in a single- or double-door (transit) tunnel version.

- Available in several alternatives of chamber heating according to the customer's requirements: heating by electricity, steam or natural gas.

- The installation can be supplied with a cooling chamber. If so, the same installation can do the heat treatment and fast and intensive cooling with reference to the technological process (slowing down the evaporation of water) and HACCP requirements afterwards.